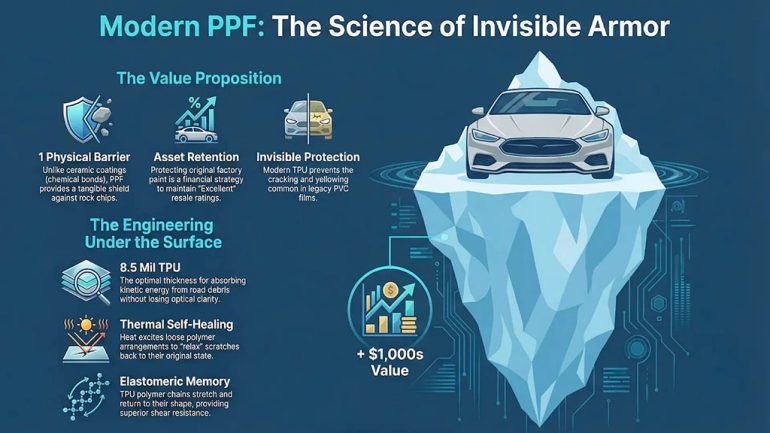

In an era where vehicle complexity has skyrocketed, the cost of cosmetic repairs has followed a similar trajectory. We have previously discussed how modern sensor arrays and composite materials make minor collision repairs disproportionately expensive. In this landscape, Paint Protection Film (PPF) has transitioned from an optional accessory to a critical layer of asset protection.

However, many enthusiasts still associate PPF with the thick, yellowing “clear bras” of the early 2000s. The reality of modern material science is vastly different. Today’s films are not merely plastic covers; they are highly engineered elastomeric barriers designed to sacrifice themselves to preserve the original factory finish.

From PVC to TPU: The Evolution of Material

To understand the efficacy of modern protection, we must look at the chemistry. Early generations of film were constructed from Polyvinyl Chloride (PVC). While durable, PVC is rigid and chemically unstable under long-term UV exposure, leading to the infamous “cracking” and “yellowing” that plagued early adopters.

The industry standard has shifted entirely to Thermoplastic Polyurethane (TPU).

- Elastomeric Properties: Unlike the rigid PVC, TPU is an elastomer. At a molecular level, its polymer chains are capable of stretching and returning to their original state.

- Shear Resistance: This flexibility allows the material to absorb the kinetic energy of road debris (gravel, salt) rather than simply acting as a hard shell that might chip.

- Optical Clarity: Modern TPU formulations are optically clear, allowing the depth of the metallic or pearlescent paint underneath to remain unobscured.

The Mechanics of “Self-Healing” (How it Works)

The term “self-healing” often sounds like marketing hyperbole, but it is grounded in simple thermodynamics. The top coat of premium PPF is engineered with loose polymer arrangements that are not fixed in a rigid lattice.

When a scratch occurs—essentially a displacement of these polymers—the introduction of heat (from the sun, a hot engine, or warm water) excites the molecules. This energy allows the polymers to “relax” back into their natural, lowest-energy state, effectively closing the gap and erasing the swirl mark.

Technical Specifications and Professional Grade Standards

When evaluating the protective capabilities of a film, thickness and elasticity are the primary metrics. Standard commercial films often range between 6-7 mils, but for impact resistance against highway debris, industry data suggests a sweet spot of 8.0 to 8.5 mils.

For example, high-performance variants like Flexippf‘s WSH Pro specifications demonstrate how an 8.5-mil Thermoplastic Polyurethane (TPU) construction provides the necessary shear resistance to deflect stone chips while maintaining the optical clarity required for luxury finishes. This balance of thickness and transparency is what separates consumer-grade wraps from professional paint protection systems.

PPF vs. Ceramic Coating: A Functional Comparison

A common point of confusion among owners is the distinction between PPF and ceramic coatings. From an engineering standpoint, they solve two completely different problems.

- Ceramic Coatings (Chemical Bond): These are liquid polymers that chemically bond to the clear coat. Their primary function is hydrophobicity and chemical resistance. They make the car easier to clean and protect against bird droppings or acid rain, but they offer virtually zero impact resistance.

- PPF (Physical Barrier): This is a tangible layer of urethane. Its primary function is impact absorption. It is the only solution that prevents rock chips and deep scratches.

The Verdict: For a “daily driver” luxury vehicle, the ideal setup is often a hybrid approach: PPF applied to high-impact zones (bumper, hood, mirrors) to stop rocks, topped with a ceramic coating for ease of maintenance.

Quantifying the ROI: Resale Value & Longevity

For the astute car owner, maintenance is a balance sheet item. The single biggest factor in the valuation of a modern classic or luxury vehicle is the condition of the original paint. Once a panel is repainted, the vehicle’s value as a “collector grade” asset diminishes significantly.

Maintaining the exterior condition is not purely cosmetic; it is a financial strategy. According to valuation guidelines from Kelley Blue Book, the difference between a car in ‘Good’ versus ‘Excellent’ condition can be thousands of dollars. Protecting the original clear coat from UV degradation and micro-abrasions is the most effective way to retain that ‘Excellent’ rating over a 5-year ownership cycle.

Key Takeaways

| Area | Key Takeaway | Impact/Data |

| Material | Shifted to TPU elastomers | Self-heals via heat thermodynamics |

| Specs | Mandate 8.0 – 8.5 mils thickness | Standard 6-7 mils fails hwy impact |

| Strategy | Hybrid model is superior | PPF for impact + Ceramic for cleaning |

| ROI | Preserves “Factory Paint” status | Retains thousands in resale value |

| Execution | Require rolled edges & custom plotting | Over-stretching reduces protection |

What to Look for in a Professional Installation

Even the highest-grade TPU film will fail if installed poorly. When vetting a shop, look beyond the price per square foot:

- Rolled Edges: A high-quality install involves wrapping the film around the edges of panels so no seams are visible.

- Custom Plotting vs. Bulk Cutting: Advanced installers use plotters to cut the film to the exact dimensions of your specific VIN, accounting for sensors and washers.

The “Stretch” Factor: Over-stretching the film to fit curves can thin the material, reducing its protective mil thickness. Skilled installers know how to manipulate the material without compromising its structural integrity.