Every gearhead knows the numbers that matter: horsepower, torque, boost pressure, and quarter-mile times. We spend hours analyzing flow charts for turbochargers and debating the merits of different ECU tunes. But there is a silent variable that often dictates the ceiling of your build’s performance and longevity: Manufacturing Process.

It’s easy to overlook how a part is made when you’re staring at a shiny polished finish, but the engineering method used to create a component defines its structural integrity, thermal resistance, and internal geometry. Whether you are building a track weapon or a street sleeper, understanding the difference between billet, forged, and cast components is the first step in true automotive engineering.

The Foundation of Performance: It Starts with the Mold

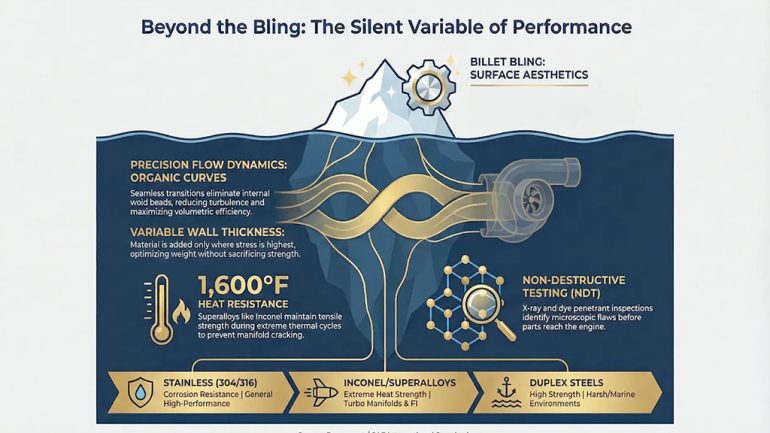

In the world of high-performance parts, there is a constant debate between machining (CNC) and casting. While CNC machining offers incredible external precision and that “billet bling” factor, it has significant limitations when it comes to complex internal geometry. You cannot machine a curved internal void if the tool cannot reach it.

Shutterstock

For components requiring intricate internal passageways—such as valve bodies or specialized pump housings—machining from a solid block simply isn’t feasible. This is where Investment Casting shines. Manufacturers like Bessercast utilize this lost-wax process to produce stainless steel and superalloy components with aerospace-level precision, ensuring that the complex geometries required for optimal fluid flow are perfectly realized without internal seams.

By using a ceramic mold created from a wax pattern, engineers can design parts where the material flows into the shape, rather than being cut away from it. This allows for undercuts, thin walls, and complex coring that would be impossible with a mill or lathe.

Analyzing the Geometry: Why Fluid Dynamics Demand Casting

When we talk about upgrading intake manifolds or exhaust headers, we are essentially managing airflow. The goal is to maximize Volumetric Efficiency—getting air in and exhaust out with minimal resistance.

Fluid dynamics hate sharp edges. Welded pipe joints, no matter how skilled the welder, often introduce ridges or slight misalignments inside the tubing. These imperfections cause turbulence, creating pockets of “dead air” that restrict flow and reduce velocity.

Precision casting solves this by allowing for organic, smooth-radius curves that are formed as a single unit.

- Seamless Transitions: No internal weld beads to disrupt airflow.

- Variable Wall Thickness: Material can be added exactly where stress loads are highest and removed where it isn’t needed to save weight.

- Optimized Runners: Runners can be tapered perfectly to accelerate air velocity into the cylinder head.

Material Science: Stainless Steel vs. Superalloys

Not all metals are created equal, and not all casting is just “cast iron.” Modern performance casting utilizes advanced metallurgy to handle the extreme heat cycles of a high-output engine.

While aluminum is fantastic for weight reduction in intake components, the exhaust side—particularly turbo manifolds and downpipes—requires materials that can withstand temperatures exceeding 1,600°F (870°C) without cracking or warping.

Common high-performance casting materials include:

- Stainless Steel (304/316): Offers excellent corrosion resistance and good high-temperature strength.

- Inconel and Superalloys: Nickel-based alloys used in Formula 1 and aerospace. They maintain Tensile Strength at extreme heat, preventing the dreaded “manifold crack” during heat cycling.

- Duplex Steels: Provide a balance of high strength and corrosion resistance, often used in marine or harsh environment applications.

Quality Control: The Difference Between a Build that Lasts and a Blown Engine

We have all heard horror stories of cheap “eBay turbos” exploding and sending shrapnel into an engine. The difference between a reliable upgrade and a catastrophic failure often comes down to quality control (QC).

Reliability isn’t accidental; it’s the result of rigorous testing protocols. Top-tier manufacturers employ Non-Destructive Testing (NDT) methods to identify microscopic flaws before a part ever reaches a vehicle. As highlighted by the American Society for Nondestructive Testing (ASNT), the importance of NDT lies in validating the fitness-for-service of components, ensuring they can withstand high-stress conditions without failure.

Before installing a critical component, check if the manufacturer uses X-ray inspections or dye penetrant testing to ensure there are no internal voids or porosity in the metal.

Key Takeaways

| Area | Key Takeaway | Impact/Data |

| Geometry | Prioritize investment casting over CNC for complex internals | Enables seamless internal passageways |

| Performance | Eliminate weld ridges via organic cast curves | Maximizes Volumetric Efficiency |

| Materials | Mandate Superalloys/Inconel for exhaust components | Withstands >1,600°F (870°C) |

| Quality | Require Non-Destructive Testing (X-ray/Dye) | Prevents catastrophic engine failure |

Conclusion: Know What You Are Installing

As you plan your next upgrade, look beyond the brand sticker and the price tag. Ask questions about the manufacturing origin. Was this part CNC machined for aesthetics, or was it precision cast for flow dynamics? Does it use generic steel, or a calculated superalloy blend?

Your engine is a complex system of thermal and kinetic energy. Treat it with respect by choosing parts that are engineered, not just fabricated.